Bathurst Mining - Upgrades to the Lubrication System at Maramarua Mine

Bathurst Mining’s Maramarua site sought to upgrade its old oil tank farm with more efficient and durable equipment. Advance Fluid Control stepped in to provide a comprehensive solution that would enhance the company's operations. This case study highlights the products and services provided by Advance Fluid Control, including self-bunded clean oil tanks, a waste oil tank, a press-fit stainless steel piping system, an Orion service reel stand, a waste oil system, a level alert system, and a heavy-duty waste oil hose reel.

The Solution:

To meet Bathurst Mining's requirements, Advance Fluid Control supplied four 5000L self-bunded clean oil tanks and a 5000L self-bunded waste oil tank. These tanks are designed to contain and store oil in a safe and efficient manner. The self-bunded feature provides an extra layer of protection, ensuring that any potential spills or leaks are contained within the tank, thus preventing environmental contamination.

To facilitate the transfer of oil to and from the tanks, we installed a press-fit stainless steel piping system. This high-quality piping system ensures efficient and reliable transportation of oil between the external tanks and the workshop. With its corrosion-resistant properties, the stainless steel piping system guarantees a longer lifespan and reduced maintenance costs.

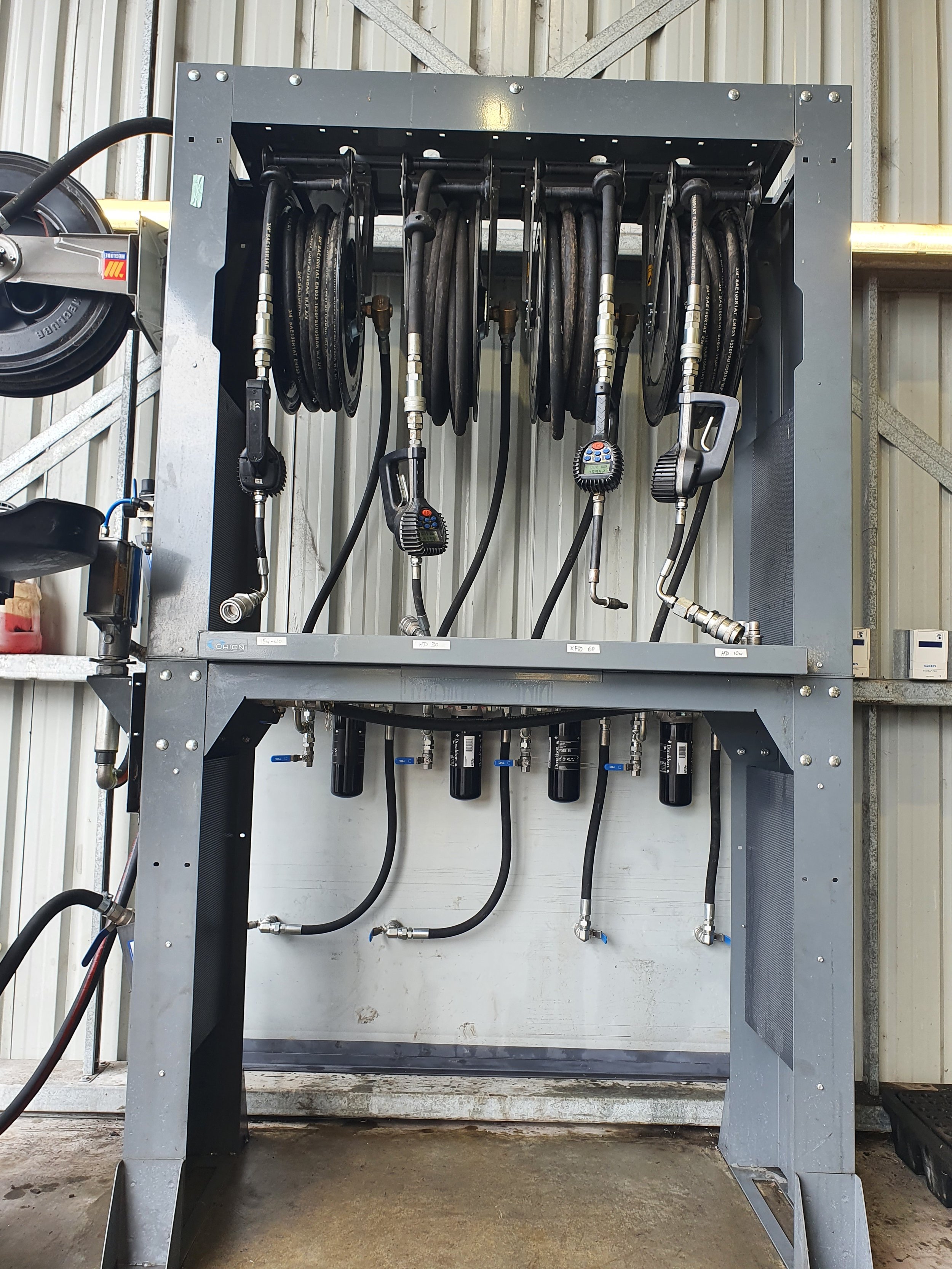

Inside the workshop, a heavy-duty Orion service reel stand was supplied. Designed to withstand tough working conditions, this reel stand provides a reliable and convenient solution and a central location for accessing hose reels and other equipment. Bathurst Mining can rely on the durability and longevity of the service reel stand to meet its daily operational needs.

A complete waste oil system and a level alert system were also supplied for handling the used oil. The waste oil system efficiently extracts large quantities of waste oil from field service vehicles. Equipped with a heavy-duty waste oil hose reel, the system provides a quick and effective method for removing waste oil, streamlining maintenance and servicing procedures. The level alert system provides a visual warning when the tank is nearly full and will also stop the waste oil pump when the tank reaches the maximum level.

The Results:

By implementing Advance Fluid Control's solutions, Bathurst Mining has experienced significant improvements in its oil storage and transfer processes. Self-bunded clean and waste oil tanks enhance safety and compliance by preventing spills and leaks. The press-fit stainless steel piping system guarantees reliable oil transportation, reducing the risk of system failures and maintenance downtime.

The inclusion of the Orion service reel stand improves the overall efficiency of internal operations. Bathurst Mining staff can easily access hose reels and other equipment, facilitating smoother workflow and minimizing unnecessary downtime.

Moreover, the waste oil system and level alert system have streamlined waste oil extraction from field service vehicles. Bathurst Mining can now extract waste oil quickly and efficiently, ensuring their vehicles are maintained at optimum performance levels.

In conclusion, Advance Fluid Control's solutions have significantly enhanced Bathurst Mining's oil storage and transfer processes. Bathurst Mining can operate with increased productivity and confidence with improved safety measures, efficient transportation systems, and reliable equipment.